welcome to pvg Indotech Machine shop facility

-

The Smart series are designed for high productivity, compact design and environmental considerations. They provide high efficiency machining thanks to the No. 40 taper spindle with maximum spindle speed of 12000 rpm and high speed feed rates.

The VERTICAL CENTER SMART 430A/530C combines productivity, high-accuracy and high-reliability, to provide the performance you have been looking for. Delivering unsurpassed value for a variety of machining operations from heavy duty machining to high speed machining.

The conventional MAZATROL SMART CNC system is designed for easy operation and programming plus high reliability Additional the CNC system can utilize both EIA/ISO format programs and conversational programming.

-

Metal stampings are manufactured components produced by a process called metal stamping or pressing. This process involves forming a piece of sheet metal into a desired shape or design using a press and a stamping die. Metal stampings are widely used in various industries for a range of applications due to their cost-effectiveness, precision, and versatility.

-

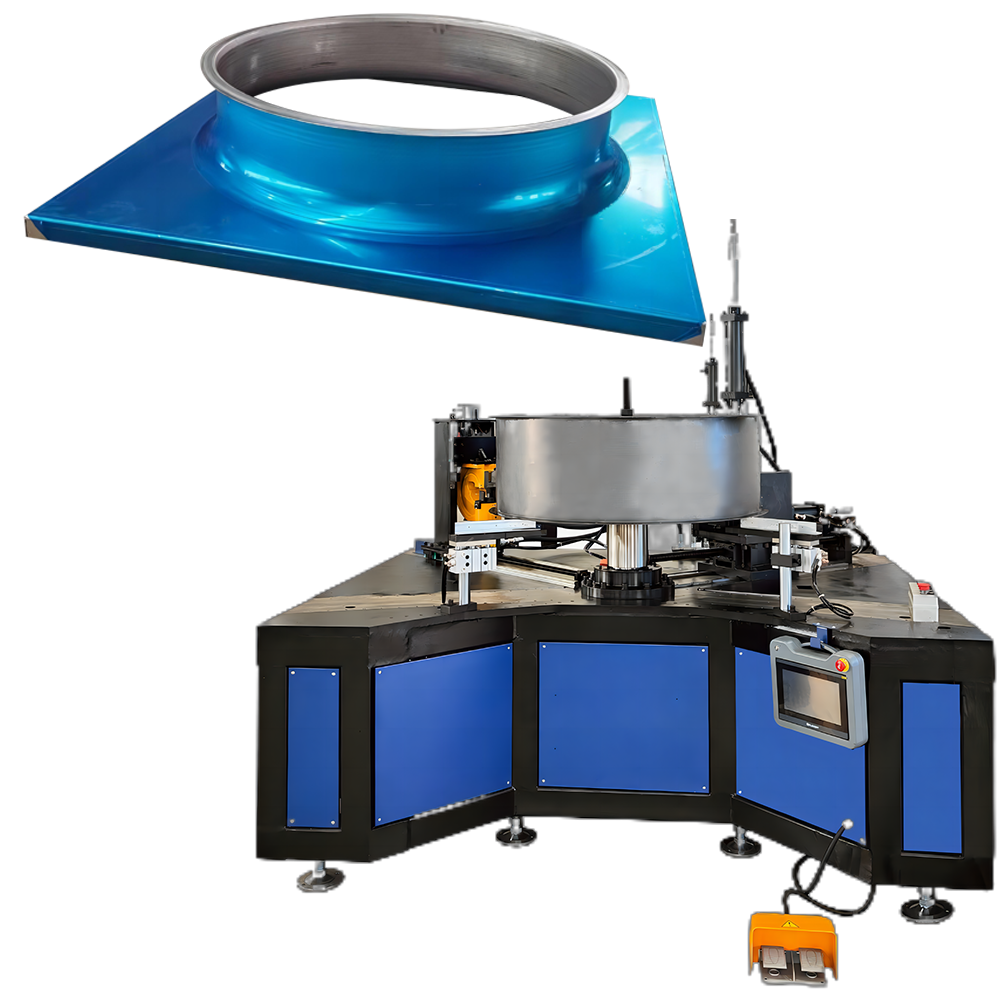

Sheet metal spinning, often referred to as metal spinning or spin forming, is a metalworking process used to create cylindrical, conical, or other axisymmetric shapes from sheet metal. This process involves a highly skilled craftsman or a specialized machine, called a metal lathe, to spin and form the metal into the desired shape. Here's an overview of sheet metal spinning manufacturing:

Sheet metal spinning is a specialized manufacturing technique that offers versatility in creating unique, often decorative, and functional components. The skill and experience of the operator play a crucial role in achieving the desired shapes and maintaining product quality.

-

Sheet metal manufacturing is a versatile and widely used process in which flat sheets of metal are transformed into various parts, components, and products. This process involves cutting, bending, and assembling sheet metal to create a wide range of items for diverse applications across industries. Here is an overview of sheet metal manufacturing:

Quality control measures are implemented throughout the manufacturing process. This includes inspections, measurements, and testing to ensure that the finished sheet metal products meet the required specifications and standards.

Sheet metal manufacturing is a foundational process in modern industrial production, providing the means to produce a wide range of products efficiently and economically. It requires skilled workers and specialized equipment to produce high-quality components and products.

-

Fabrication is the process used to manufacture steelwork components that will, when assembled and joined, form a complete frame. The frame generally uses readily available standard sections that are purchased from the steelmaker or steel stockholder, together with such items as protective coatings and bolts from other specialist suppliers.

Although a wide range of section shapes and sizes are produced, the designer may find that the required section size is not available. In this case, built-up girders may be fabricated from plate. Sections and plate girders may also be strengthened by stiffening the web or flanges depending upon the load to be carried.

“Passionately curious to innovate process improvements with our customers in manufacturing and machining domain towards increasing precision engineering.

-

Automobile companies are at the forefront of innovation, driving transformative changes in the pursuit of sustainability. From electric vehicles (EVs) to hydrogen-powered engines, the industry is prioritizing eco-friendly solutions to reduce carbon emissions. Companies like Tesla, Toyota, and Ford are investing heavily in renewable energy integration, autonomous driving technology, and recyclable materials to create vehicles that are not only efficient but also environmentally responsible. This shift is not only a response to consumer demand but also aligns with global climate goals, ensuring a cleaner and greener future for generations to come.

.jpg)